Issue 1 (2013) Volume 6

Issue Highlights:

Qualification of the pore and indentation hardnessmeasurement on thermally sprayed coatings

The verifiability of porosity and hardness measurements on thermally sprayed coatings frequently constitutes a problem. In addition to external influences (e.g. the subjective perception of the person taking the measurem...

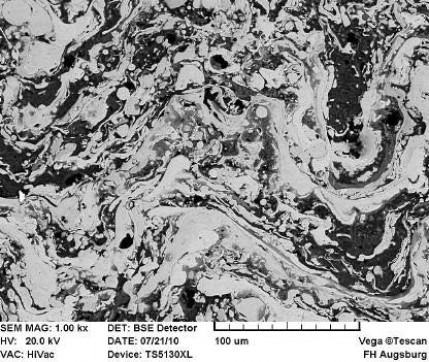

The determination of elastic moduli of thermallysprayed freely formed bodies

Various procedures which serve to establish the elastic moduli E of coats are compared with each other and assessed in this article. The knowledge of the elastic moduli of thermally sprayed coats is of particular interes...

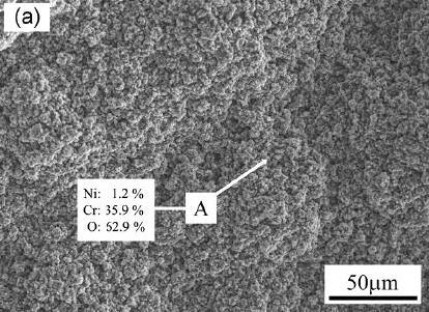

Wear and high-temperature corrosion behaviorof a wire-arc sprayed NiCrB coating

A new NiCrB cored wire was used to produce protective coatings for components used in high-temperature environment by wire-arc spraying process. The microstructure, wear resistance and high-temperature corrosion behavior...