Adaptive Path Planning for Additive Manufacturing of Freeform Geometries Using Cold Spraying

Authors: Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann, M. Sc. Jonas Zajaczkowski, Dr.-Ing. Ingor Theodor Baumann, M. Sc. Dennis Möllensiep, Prof. Dr.-Ing. Bernd Kuhlenkötter

DOI: https://doi.org/10.53192/TSB202502104

Cold Spray Additive Manufacturing (CSAM) offers a promising process for the production and repair of metallic

components, particularly those made of temperature-sensitive materials such as copper or aluminum. Unlike

thermal processes, CSAM relies on the plastic deformation of particles through high-velocity impact,

thereby avoiding thermal effects on the spray material and the substrate. This characteristic opens new application

fields but also presents specific requirements on process planning and system integration

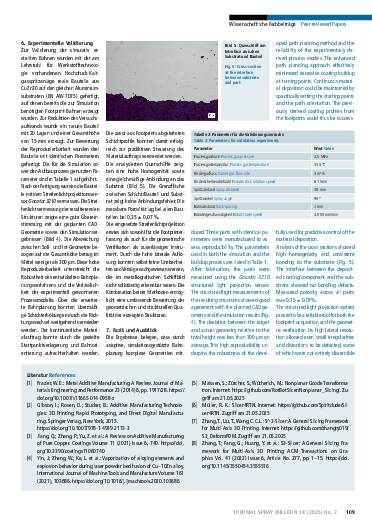

To address these challenges, an adaptivepath planning system was developed that considers the characteristics

of continuous material deposition and the limited degrees of freedom of robot-guided cold spraying systems.

Key components of the system include a modified slicer for generating non-planar coatings, automated

toolpath orientation based on part geometry and data-driven integration of empirically determined footprint

geometries. The latter enables realistic predictions of coating formation and was validated for different materials through experimental investigations. The system was successfully implemented in a robotic cell and tested using three-dimensional demonstrator parts. The results show high dimensional accuracy, homogeneity and cohesion of the deposited coatings.

Pages: 104 - 110

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription