Control of Powder Streams in Coating Technologies

Authors: Dr.-Ing. Andreas Wank, Enrico Hauser, M. Eng. Christian Schmengler, B. Eng. Melissa Mülln, Dipl.-Ing. Tim Königstein

DOI: https://doi.org/10.53192/TSB20250296

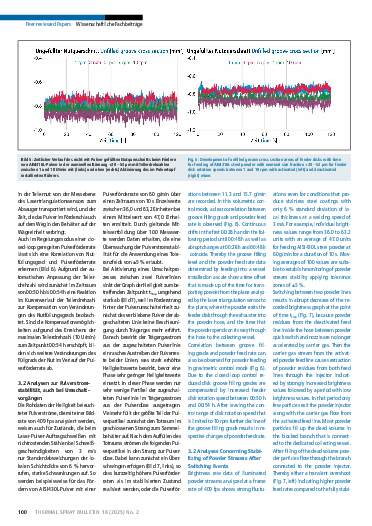

The filling grade of feeder disk grooves is monitored by a laser triangulation sensor. A correlation between groove

filling grade and powder feed rate is proven. Applicability of groove filling grade data for realization of effective

control loops to secure constant powder feed rates and for determination of optimal hardware setups and parameter

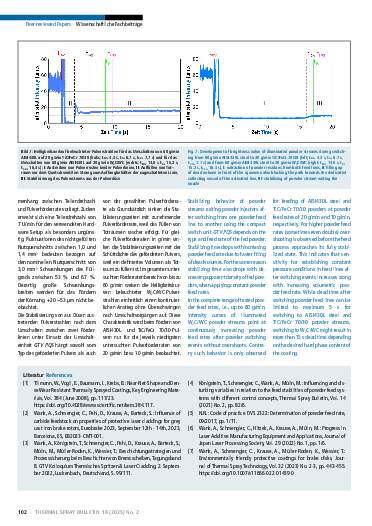

settings of disk type feeders are discussed. Stabilizing behavior of powder streams after switching between

different powder feed lines using a compact squeeze valve based powder quick switch unit is studied

by digital analyses of images taken from illuminated powder streams that exit injectors. The time to re-establish

stable powder streams depends on apparent density and feed rates of powders.

Pages: 96 - 103

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription