Numerical Simulation of the Gas and Particle Flow in the Combustion Chamber and the Exit Nozzle of the HVOF Internal Diameter Process

Peer-reviewed Papers

Authors:

Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann,

Prof. Dr. Jochen Schein,

Dr.-Ing. Stephan Zimmermann,

Dipl.-Ing. Manuel Pinho Ferreira,

Ahmad Said,

Dr.-Ing. Ingor Theodor Baumann

DOI:

https://doi.org/10.53192/TSB20250288

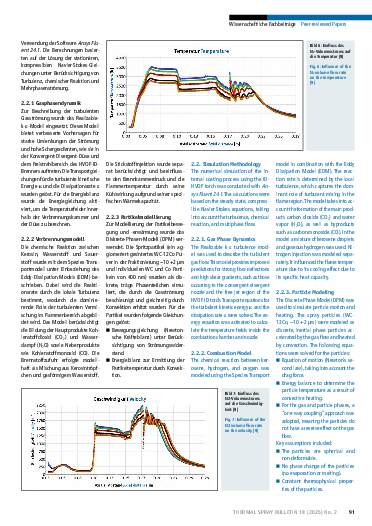

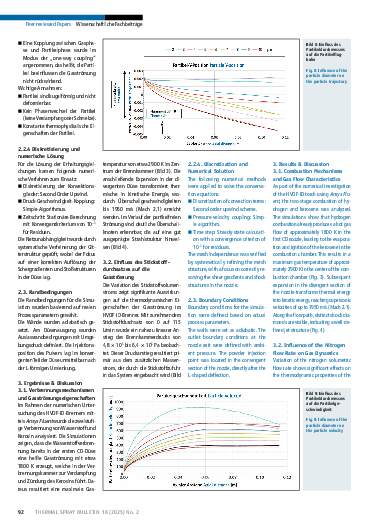

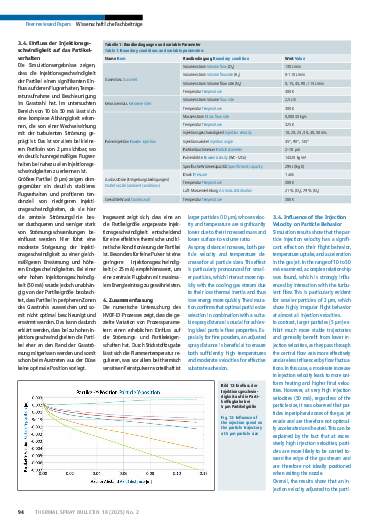

This study focuses on computational fluid dynamics (CFD) simulations of the HVOF-ID (High Velocity Oxy-Fuel – Internal Diameter) process with additional nitrogen injection into the combustion chamber (Warm Spray Process) for the internal coating of components. The simulations are carried out using an ID-RED type internal coating torch, with particular emphasis on the combustion chamber, the L-shaped barrel, and the expansion nozzle region. A detailed, experimentally

validated simulation model based on Ansys Fluent was employed to investigate gas and particle flow, heat transfer, and combustion processes in an ID-HVOF torch. The geometry was digitized by means of X-ray computed tomography and

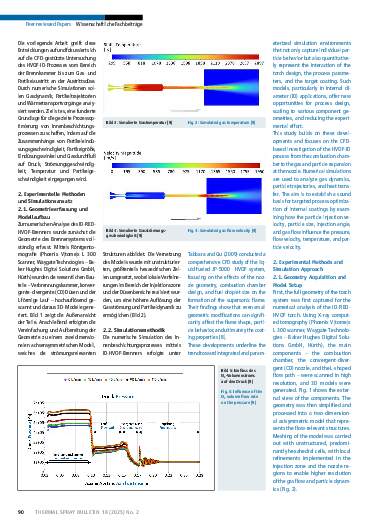

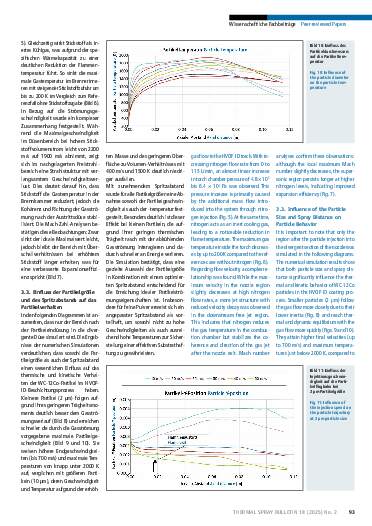

processed into an axisymmetric model. The computational domain was discretized with refined mesh sizes in the nozzle and combustion chamber regions. The simulations reveal the influence of variable parameters such as nitrogen flow rate, particle size, spray distance, and injection velocity on the temperature and velocity distributions as well as on the

flight behavior of WC-12Co particles. The results of this study demonstrate that fine particles exhibit particularly

favorable thermo-kinetic properties at short spray distances and with adjusted injection velocity. In this way,

sufficient heat and momentum transfer from the flame to the particles can be achieved even at short spray distances,

enabling effective coating. Nitrogen injection strongly affects flame temperature, combustion chamber pressure

as well as the shape of the free jet. Overall, this study provides a solid foundation for process optimization

of the HVOF-ID technique, particularly with regard to efficiency, reproducibility, and coating quality.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.