Issue 1 (2017) Volume 10

Issue Highlights:

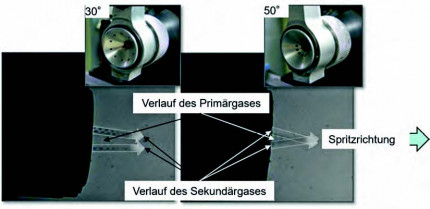

Shielding of the spraying jet during the arc sprayingof NiTi in order to reduce the oxide formation

As a rule, the process-induced, intensive heat input into the spraying material during arc spraying in the presence of air oxygen (atomising gas) leads to the oxidation of the sprayed particles. Substantially increased o...

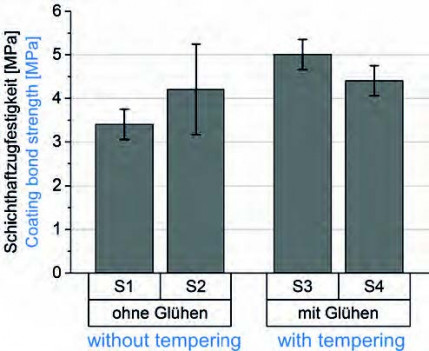

Investigation of influencing factors on the transferof wire arc sprayed Zn coatings for the metallisationof plastics parts

In a current study, a new approach for the efficient production of metallised plastics parts, the so called In-Mould-Metal-Spraying (IMMS), is being developed. A Zn coating is at first thermally sprayed onto mould cavity...

Development of advanced Cr2O3 coatings by thermalspraying with suspensions

Advanced coatings with improved properties have been developed by spraying water-based Cr2O3 suspensions with High Velocity Oxygen Fuel Spraying (SHVOF). In comparison to conventionally sprayed coatings, suspension spray...