Increasing the Corrosion Resistances of Arc-Sprayed Aluminium Coatings by Means of Oxygen-Free Process Control

Peer-reviewed Papers

Authors:

Dipl.-Ing. Manuel Rodriguez Diaz,

M. Sc. Alexander Schnettger,

Dr. rer. nat. Ulrich Holländer,

Maik Szafarska,

René Gustus,

Prof. Dr.-Ing. habil. Kai Möhwald,

Prof. Dr.-Ing. Hans Jürgen Maier

DOI:

https://doi.org/10.53192/TSB20250124

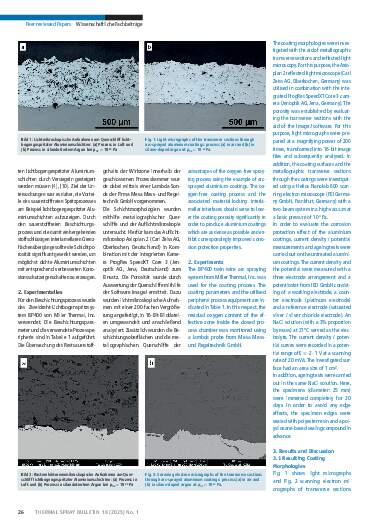

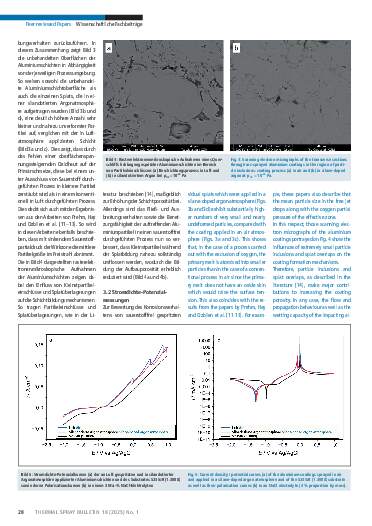

This paper investigates the corrosion protection properties of aluminium coatings which were applied to steel substrates in different process atmospheres. The twin-wire arc spraying (TWAS) process was used in order to produce the coatings not only in air but also in an oxygen-free atmosphere consisting of silane-doped argon. The addition of diluted monosilane caused the complete conversion of the residual oxygen in the coating chamber into amorphous silicon dioxide and hydrogen, thus permitting the formation of oxide-free coatings. The objectives of the procedure were to decrease the coating porosity due to the improved wetting behaviour of the oxide-free particles and to improve the corrosion protection in this way. The results show that the oxygen-free process control leads to dense aluminium coatings which exhibit substantially higher corrosion resistances than those of coatings conventionally applied in air since potential corrosion paths are reduced significantly.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.