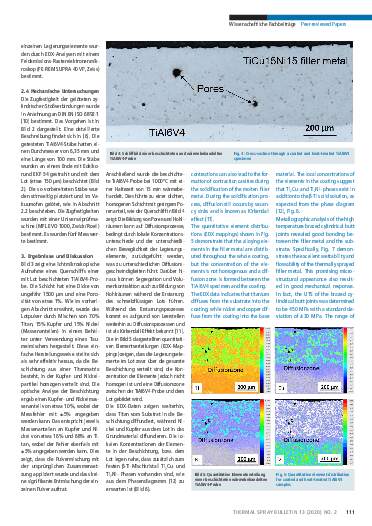

Application of a titanium filler metal by cold gas dynamic spraying

Authors: Dr. rer. nat. Martin Nicolaus, Prof. Dr.-Ing. habil. Kai Möhwald, Prof. Dr.-Ing. Hans Jürgen Maier

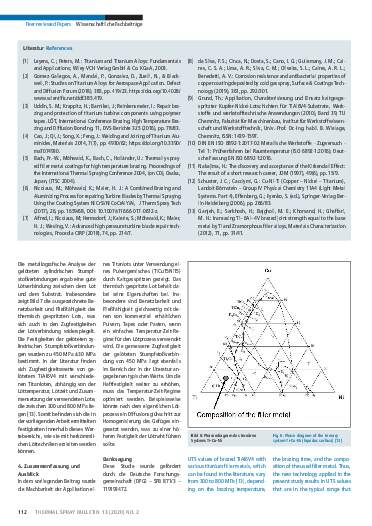

Pure titanium and titanium alloys find numerous applications in lightweight design. These materials are corrosion and oxidation resistant, have a high strength to weight ratio, excellent biocompability and a density which is about 50% lower compared to the one of steel. Typical fields of applications are mechanical and plant engineering, automotive manufacturing, biomedical technology and aerospace. For joining titanium alloys, brazing processes in a high vacuum furnace are often used. In the present study, TiAl6V4 specimens were coated with a powder mixture by cold gas dynamic spraying. The powder consisted of 70% titanium, 15% copper and 15% nickel (mass fractions), representing a common titanium filler metal. The coated specimens were brazed in a high vacuum furnace at 1000°C and the formed microstructure and ultimate tensile strengths (UTS) were investigated. The measured UTS of 450 MPa lies in the range of typical UTS values reported in the literature.

Pages: 108 - 113

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription