Titanium-carbide-reinforced iron-based materials -A cost-favourable solution for wear protectionapplications

Authors: Prof. Dr.-Ing. Kirsten Bobzin, Dr.-Ing. Thomas Schläfer, Dipl.-Geow. Katharina Richardt, Dipl.-Ing. Thomas Warda, Dr.-Ing. Guido Reisel

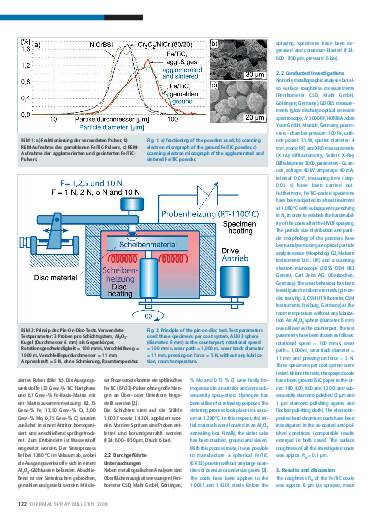

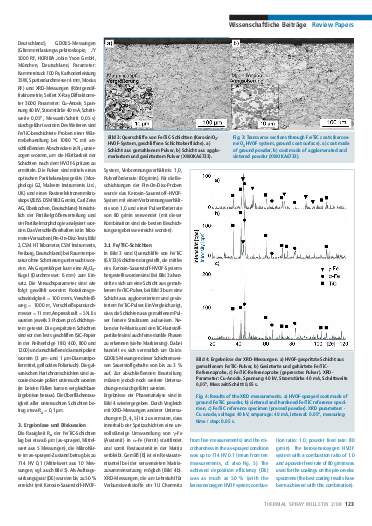

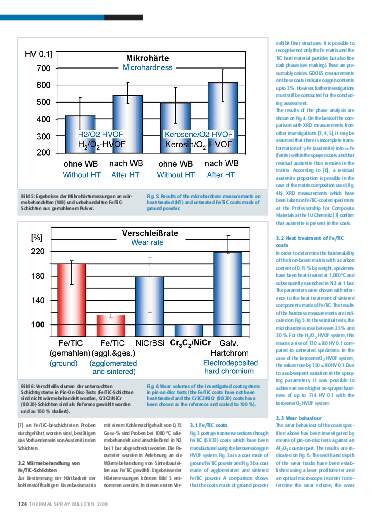

Nowadays, thermally sprayed coats are widespread in industry for wear protection applications. Conventional coat systems are WC/Co or Cr3C2/NiCr. Because of their high carbide content of more than 75 % by weight, they possess excellent wear protection properties. However, the raw material prices for the matrix materials such as cobalt or nickel are subject to extreme fluctuations and are well above the prices for iron. One alternative concept to the conventional tungsten or chromium carbide coats is therefore based on cost-favourable iron-based materials with titanium carbide reinforcement (Fe/TiC). Depending on the carbon content, the iron-based materials offer a hardenable matrix for improved wear properties. The objective of the paper presented here is to investigate the potential of such iron-based materials as a cost-favourable alternative to conventional carbide-based coats for wear protection applications. Investigations have been conducted into the processing of Fe/TiC powders with two different HVOF systems. The Fe/TiC coats have been analysed with regard to the microstructure, the hardness and the phase composition. Tribometer investigations (pin-on-disc tests) have been conducted in order to establish the wear behaviour. The Fe/TiC coats have been compared to reference coat systems in order to classify the efficiency. Furthermore, the Fe/TiC coats have been heat-treated in order to establish the hardenability of the ironbased matrix after the thermal spraying process. Due to this heat treatment process, it was possible to raise the microhardness

by up to 30 %. The results of the pin-on-disc tribometer investigations show that the wear behaviour (wear rate) of the Fe/TiC coats (against an Al2O3 counterpart) is comparable with that of the tested reference

systems. On the basis of the results, it may be said that TiC-reinforced iron-based coats offer a cost-favourable solution for wear protection applications. Taking account of current material prices, as much as 50 % of the

material costs could be saved with such Fe/TiC coat systems (e.g. compared to Cr3C2/NiCr 80/20).

Pages: 120 - 126

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription