Coating development for potential application in PEM water electrolysis

Authors: Prof. Dr.-Ing. Kirsten Bobzin, Dr.-Ing. Lidong Zhao, M. Sc. Hendrik Heinemann, M. Sc. Elisa Olesch, M. Sc. Katja Radermacher

DOI: https://doi.org/10.53192/TSB20230142

Polymer electrolyte membrane water electrolysis (PEMWE) is an electrolysis technology for hydrogen

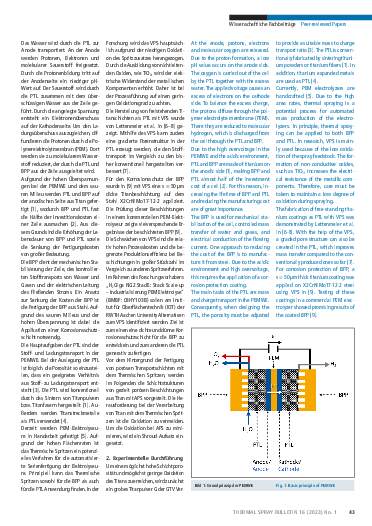

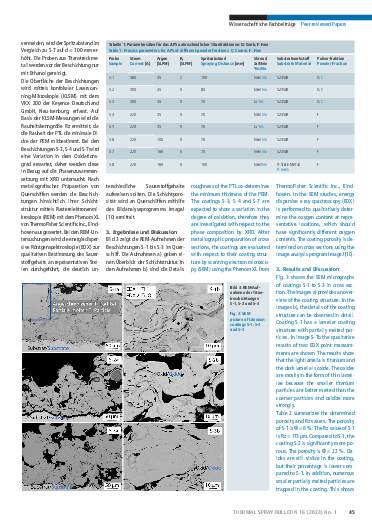

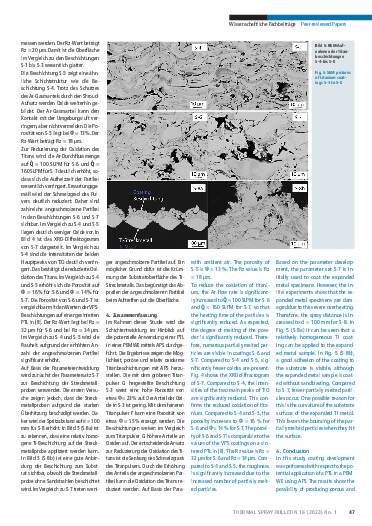

production. The bipolar plate (BPP) and the porous transport layer (PTL) made of titanium are two costly components in the electrolyzers of PEMWE. Research has already evaluated the use of vacuum plasma spraying (VPS) for the fabrication of BPP and PTL. In this publication, the fabrication of PTL using atmospheric plasma spraying (APS) is investigated. By eliminating the need for vacuum technology, process costs could be reduced. In the paper, two titanium powders are processed with the three-cathode plasma spraying. First, the

spraying parameters are developed in terms of coating porosity and oxidation of titanium with steel substrate.

Based on this, thin titanium exponded metals are coated as PTL. The coating structure and the phase composition of the coatings are investigated by scanning electron microscopy (SEM) and X-ray diffraction

analysis (XRD).

Pages: 42 - 48

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription